Product Information

VISCOUS FLUIDS In general, the more viscous the fluid, the lower the heat transfer is. This means that very viscous fluids require a very large heat transfer area. Scraped surface heat exchangers vigorously mix the fluid, which helps to move the fluid to and from the heat exchange surface. This increases heat transfer rates, so the total area required for heat exchange is reduced.

HRS SOLUTIONS For difficult heat transfer applications, with high viscosities and where fouling can become a problem, the preferred option is a scraped surface heat exchanger. Scraped surface heat exchangers keep heat transfer high and the heat transfer surface is constantly cleaned. HRS offers two technologies for scraped surface heat transfer: the patented HRS Unicus Series which reciprocates and R Series which rotates, each designed for specific needs.

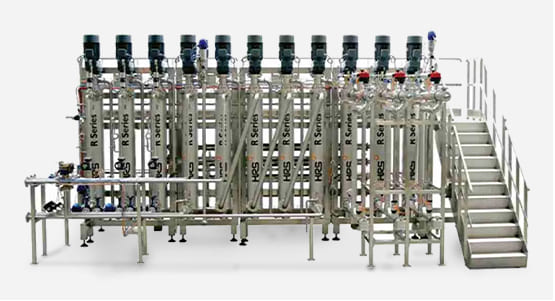

ROTATING SCRAPED SURFACE HEAT EXCHANGERS – HRS R SERIES

The HRS R Series is a scraped surface heat exchanger designed for the most difficult heat transfer applications, for example where very high viscosities and highly fouling fluids need heat treatment.

Unlike the HRS Unicus Series, where the scraper movement is reciprocal, the HRS R Series technology uses a rotary scraper rod. This scraper rod can reach velocities up to 300 rpm resulting in very high levels of shear and mixing at the heat transfer surface; dramatically increasing the heat transfer rate.

In addition to the standard R series a heavy duty version is available. The HRS RHD Series has been developed for the more demanding applications with extreme viscosities. The RHD has all the features and benefits of the standard R Series but with increased motor size and scraping rods. Extra mounting supports for the scrapers and motor enable the unit to be used under challenging conditions.

The R and RHD Series has been developed for both hygienic and industrial applications. Each inner tube contains a scraper bar fitted with a helical screw which rotates at high speed and enhances flow through the tube whilst reducing pressure drop. In addition, the continuous scraping action eliminates fouling on the inner tube wall, ensuring that the heat transfer area is clean at all times.

The R and RHD Series are suitable for heat transfer applications on a wide range of products and applications:

- Processes

- Heating

- Cooling

- Pasteurisation

- Crystallisation

- Evaporation

Some of the unique features of the R and RHD Series include:

- Large heat transfer area

- Single and multiple tube options, all with removable tubes

- Reduced pressure drop

- High level of product recovery

- Low noise level gearbox

- Energy Efficient

- Multipass version available

- Viscous food products: Dairy and vegetable concentrates (condensed milk, tomato paste, purees, juice concentrates, honey, butter, margarine), nut butters

- Convenience foods: Chocolate-based dressings, ketchup, cheese sauce, spreads

- Protein: Egg-based products, minced meats

- Cosmetics: Lotions, cream, gels