Product Information

With hassle-free operations and maintenance including pharmaceutical, chemical, agrochemical, fertilizer, oil and fats, cement, steel, petrochemical, power generation, and food and beverage processing. HRS also designs and manufactures ECOFLUX* Smooth Shell and Tube Heat Exchanger for various industrial applications like heating, cooling, condensing, re-boiling and many more such processes. Equipped with the expertise of ASME ‘U’ stamp, TEMA accredited and quality norms of ISO 9001:2015.

With hassle-free operations and maintenance including pharmaceutical, chemical, agrochemical, fertilizer, oil and fats, cement, steel, petrochemical, power generation, and food and beverage processing. HRS also designs and manufactures ECOFLUX* Smooth Shell and Tube Heat Exchanger for various industrial applications like heating, cooling, condensing, re-boiling and many more such processes. Equipped with the expertise of ASME ‘U’ stamp, TEMA accredited and quality norms of ISO 9001:2015.

INFORMATION ABOUT PRODUCT

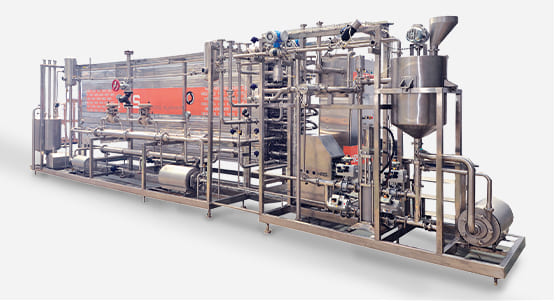

- ECOFLUX* ‘DT’ series heat exchangers with specially designed ‘dimpled’ pattern tubes for rapid, homogeneous and efficient heat transfer

- HRS Hygienic Piston Pump – BP Series is the core of the system for handling particulates

- Closed loop hot water system with ECOFLUX* CTHE for steam economy

- Sanitary type valves, feed/Balance Tank

- Stainless steel CIP pump for faster cleaning of heat exchanger and piping

- PLC based control panel with scada

- Specially designed ECOFLUX* (dimple) corrugated tube heat exchangers

- HRS Hygienic Piston Pump – ‘BP’ Series

- Closed loop hot water system consisting of ECOFLUX* ‘K’ series tubular heat exchanger for steam economy

- Sanitary type flow diversion valves

- Integrated CIP System

- PLC based Control panel with SCADA

- Rapid, homogeneous and efficient heat transfer

- Retention of natural colour and flavour of the product

- Processing of whole dices leaves without breakage

- Hygienic design

- Better product shelf life

- Controlled process automation for easy operation

- Hassle-free maintenance

- Processing of diced fruits for end use in

- Fruit bases & toppings

- Ice Cream

- Custards & puddings

- Soups

- Jams and Marmalades

- Sauces with particles

- Fillings and coatings

- Processing of Ready to eat convenience foods, Indian curries, mixes, mash, purees

- Blanching and chilling of vegetables

- Continuous rice cooking