HRS Process Systems Ltd. have acquired exclusive rights by the way of license manufacturing agreement for design, manufacture, supply and service of Plate Heat Exchangers, with FUNKE Waermaustauscher GmbH! A large range of standard and special designs of the Brazed Plate Heat Exchanger can cover a wide spectrum of process applications across industrial and domestic sectors as an economical solution for heat transfer.

HRS Process Systems Ltd. have acquired exclusive rights by the way of license manufacturing agreement for design, manufacture, supply and service of Plate Heat Exchangers, with FUNKE Waermaustauscher GmbH! A large range of standard and special designs of the Brazed Plate Heat Exchanger can cover a wide spectrum of process applications across industrial and domestic sectors as an economical solution for heat transfer.

Product Information

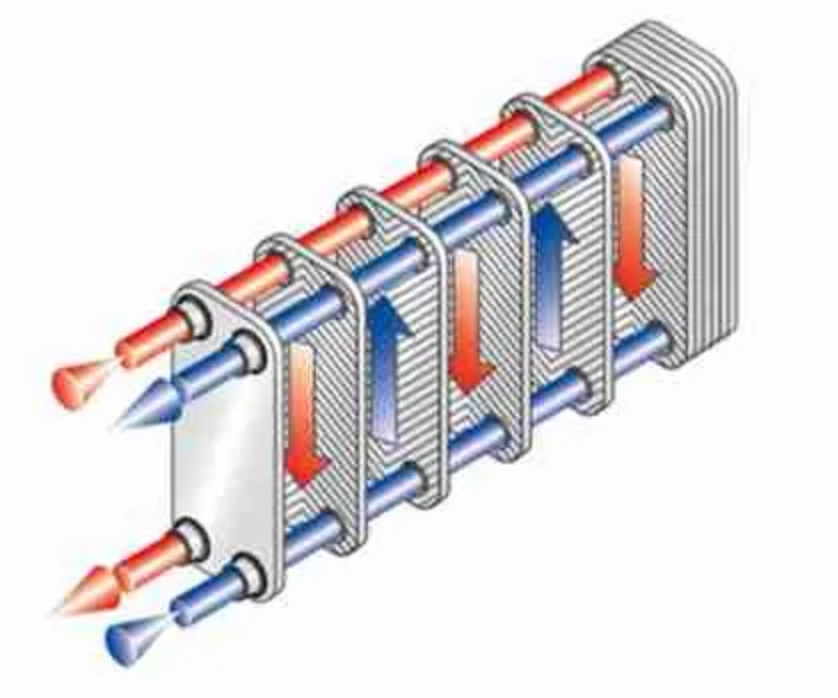

Our brazed plate heat exchangers (PHE) consist of embossed stainless steel plates that fit into one another and are vacuum brazed with copper or nickel to form a compact pressure-proof unit. During assembly, every second plate is staggered by an angle of 180° creating specific gaps for product flow.

The design and construction of brazed plate heat exchangers enable to create a highly turbulent flow for the most effective heat transfer, even in case of low volumetric flow rates and reduces the risk of fouling to a minimum.

These brazed plate heat exchangers can perform in the range of 2.0 to 6000 kW.

PHE Material

For plates, the material is stainless steel 1.4401 / 316

Solder is with copper or nickel as per process requirement and best material compatibility.

Media

Brazed PHEs are most suitable for oil/ water, water/ water, gas/ liquid (condensation), or such specific media as per process and design.

The maximum operating pressure for efficient performance is up to 30 bar; the Operating temperature is between -160°C to a maximum of +200°C.

TPL Series

The powerful unit for top heat transfer rates in case of media with average viscosity and high viscosity. Design the TPL unit has special turbulators placed between the flow of gaps and by diagonal media flow together with large diameter connections very high heat exchangers rates are reached.

GPL Series

Heat transfer plates with V-corrugation for universal application in case of media with low velocity. GPL series has thermally optimized plate corrugation which produces highly turbulent flow even in case of low mass flow. GPLS series with double plates as the safety heat exchanger types is also available

- Compact design, light weight

- Optimum heat transfer by means of special plate embossing and installed turbulators

- Series for special applications like oil and gas cooling

- Durable and easy-to-maintain

- Extensive application know-how, covering a lot of industrial branches and further heat transfer technologies

- Perfect fitment for process due to extensive range of variants, sizes and materials

HRS FUNKE Plate Heat Exchangers are used across process industries for various applications designed with MOC compatibility, Our Plate Heat Exchangers are efficiently suited to a range of industries.

In chemical, pharmaceutical, mechanical engineering, on and offshore sector, power, shipbuilding, compressors, piston and turbo machines, steel, surface treatment, automotive, paper and pulp, HVAC, extraction plants, HRS FUNKE Plate Heat Exchangers are used for heating and cooling of water, various type of oils, suspensions, infusion solutions, chemicals, acids etc.

In the food and milk processing sector, a range of heating, cooling, pasteurization and heat recovery for milk and juices.

Spares and Support Services

Our wide sales and service reach ensures quick availability of spares, systems maintenance and overhauling services enables to fulfil customer requirements in the thermal processing process industry.

Opening Of Plate Heat Exchanger

Cleaning Of Plate Heat Exchanger

Replacement Of Plates and Gaskets

Reassembly

Hydro-testing

Checking Of Defect

Availability of Genuine FUNKE Spares

FAQ’s

We firmly believe the success of our company and our future depends on the knowledge, talent, strength and dedication of our employees. We are proud of the diverse team. To fulfil the ambitious growth plans, we are looking forward to expanding the current size by offering the following positions:

What is brazed plate heat exchanger?

Our brazed plate heat exchangers (PHE) consists of embossed stainless steel plates fit into one another and vacuum brazed with copper or nickel to form a compact pressure-proof unit. During assembly, every second plate is staggered by an angle of 180° creating specific gaps for product flow. The design and construction of brazed PHE enable to create a highly turbulent flow for most effective heat transfer, even in case of low volumetric flow rates and reduces the risk of fouling to a minimum.

How to size a brazed plate heat exchanger?

Size and type will depend on what product is going to be processed, its temperature/ pressure/ flow parameters, and capacity of the process plant. It will also depend on how much space is available in the plant. It will also depend on the chemical properties of the product/ fluids, design is checked on certified software and suitable type & size of plate is finalized. After finalization of plates suitable plate heat exchanger is offered. plate heat exchangers can be offered with a heat transfer area of upto 2400 m2. A wide range of variant models with optimal thermodynamic designs suited for different industries and a spectrum of applications.