Be it preparation of raw materials through husking, crushing, cleaning, extraction through boiling, filtering and solvent extraction, or further processes like degumming, neutralization, deodorization and subsequent refining, advanced technology from HRS has enabled to support the processing of these materials with specialized solutions for saving, recovery and re-utilization of energy, thereby enhancing the overall efficiency of the plants.

Applications of Heat Exchanger in Oil & Fats Industry

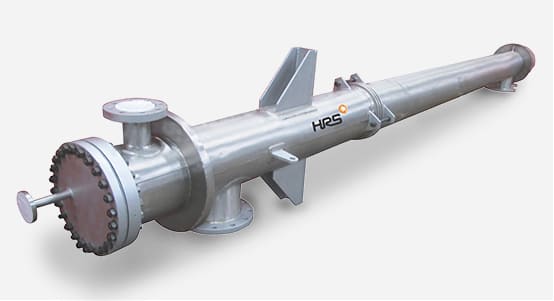

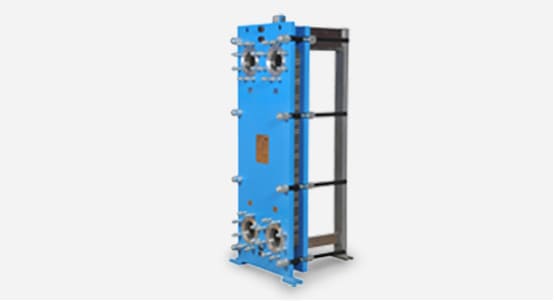

ECOFLUX* Corrugated tube heat exchangers (K , MI, DT, AS Series) & HRS Funke plate heat exchangers (PHE)

- Condenser

- Edible Oil Heater/Cooler

- Thermic Fluid Heater

- Edible Oil Heat Recovery (Oil to Oil) & (Oil to Service)

- Fatty Acid Heater/Cooler

corrugated tube heat exchanger for fatty acid process applications

ECOFLUX* CTHE as high temperature edible oil heater using steam

ECOFLUX* CTHE as high temperature edible oil heater using Thermic Fluid for Oleochemicals

ECOFLUX* corrugated tube exchanger for high pressure cocoa butter heater

ECOFLUX* smooth tube heat exchanger for high pressure heating application

HRS FUNKE Plate heat exchanger for various fluid heating cooling processes