At HRS with detailed understanding of the processes and technical expertise appropriate heat transfer solution is selected and it is customized to suit the plant, process, temperature, pressure & capacity requirements of the various OEM industry customer.

At HRS with detailed understanding of the processes and technical expertise appropriate heat transfer solution is selected and it is customized to suit the plant, process, temperature, pressure & capacity requirements of the various OEM industry customer.

APPLICATIONS

HRS heat transfer solutions give effective results in following sectors as well:

- OEMs

- Textile

- DG sets

- Automotive

- Breweries/ Distilleries

- HVAC (Heating ventilation air-conditioning)

- Effluent Treatment

- Paint

- Rubber

- Tyres

- Water Treatment

- Herbal Spices Extracts

- Flavors and fragrances

- Chloro Alkali

- Marine

- Sugar

- Starch

- Oleoresins

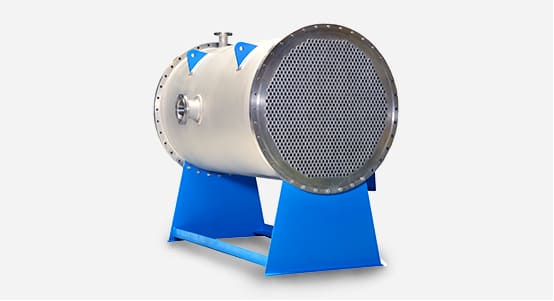

ECOFLUX corrugated tube heat exchanger as dye solution cooler/water heater

HRS FUNKE plate heat exchanger as induction furnace cooler

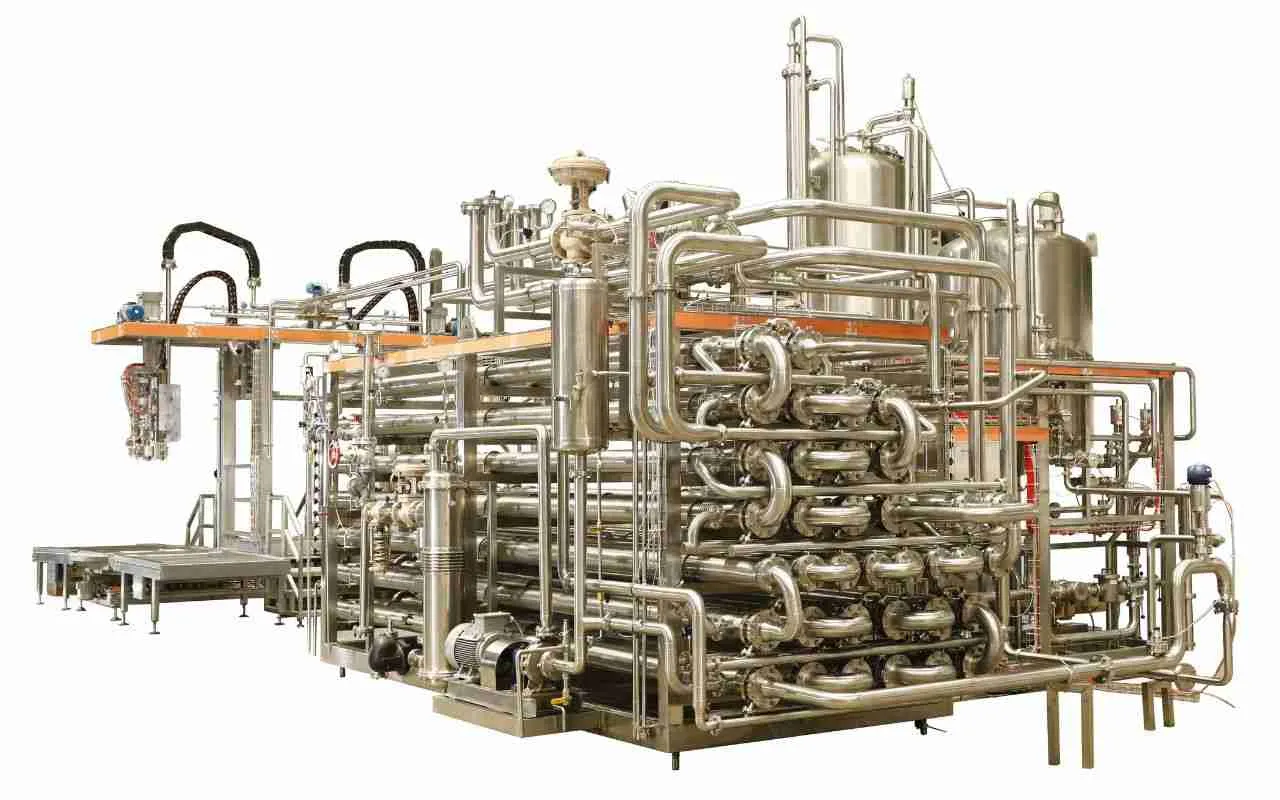

ECOFLUX corrugated tube based modular skid engine coolant Cooling

HRS FUNKE plate heat exchanger based water heating system