Fertilizer manufacturing is a complex chemical process and comprises of a lot of units for processing different kinds of material. This is processed through boilers, heat exchangers, cooling towers, wastewater treatment, gas heaters/coolers, and proper storage facilities for the end product. Commonly produced fertilizers are phosphatic or nitrogenous in the constitution.

HRS Heat exchangers are proven to increase efficiency and reduce maintenance thereby saving energy and costs. HRS has proven to “fertilize” plant operations with better productivity in processes and reap new rewards for our customers.

Applications of heat exchanger in the fertilizer industry

ECOFLUX* Corrugated tube heat exchangers (K, MI, DT, AS Series) & HRS Funke plate heat exchangers (PHE)

- CO2 Gas Cooler

- Thermic Fluid Cooler & Heater

- Natural Gas Heater

- Process Water Heater/Cooler

- Distillation Pre heater

- Vacuum Condenser

- Ammonia Condenser

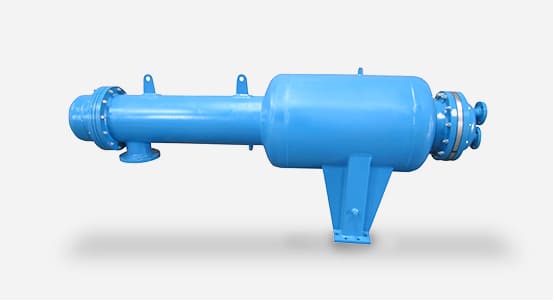

3rd stage intercooler/ after-cooler for compressor for fertilizer plant

ECOFLUX* Corrugated tube heat exchanger as Cooler for Urea Plant

ECOFLUX* smooth tube heat exchanger as gas cooler