HRS has made inroads into the varied segment of pulp processing.

Key applications such as pre-heating, pasteurisation, aseptic sterilisation, aseptic filling and evaporation have shown substantial enhancement in process hygiene, capacity enhancement and increase in the shelf life of the processed end products with HRS food processing systems.

HRS has made inroads into the varied segment of pulp processing.

Key applications such as pre-heating, pasteurisation, aseptic sterilisation, aseptic filling and evaporation have shown substantial enhancement in process hygiene, capacity enhancement and increase in the shelf life of the processed end products with HRS food processing systems.

RANGE OF FOOD PROCESSING SYSTEMS FOR MANGO, GUAVA, ORANGE, POMEGRANATES, PAPAYA, PINEAPPLE, TOMATO AND MANY MORE FRUITS & VEGETABLES

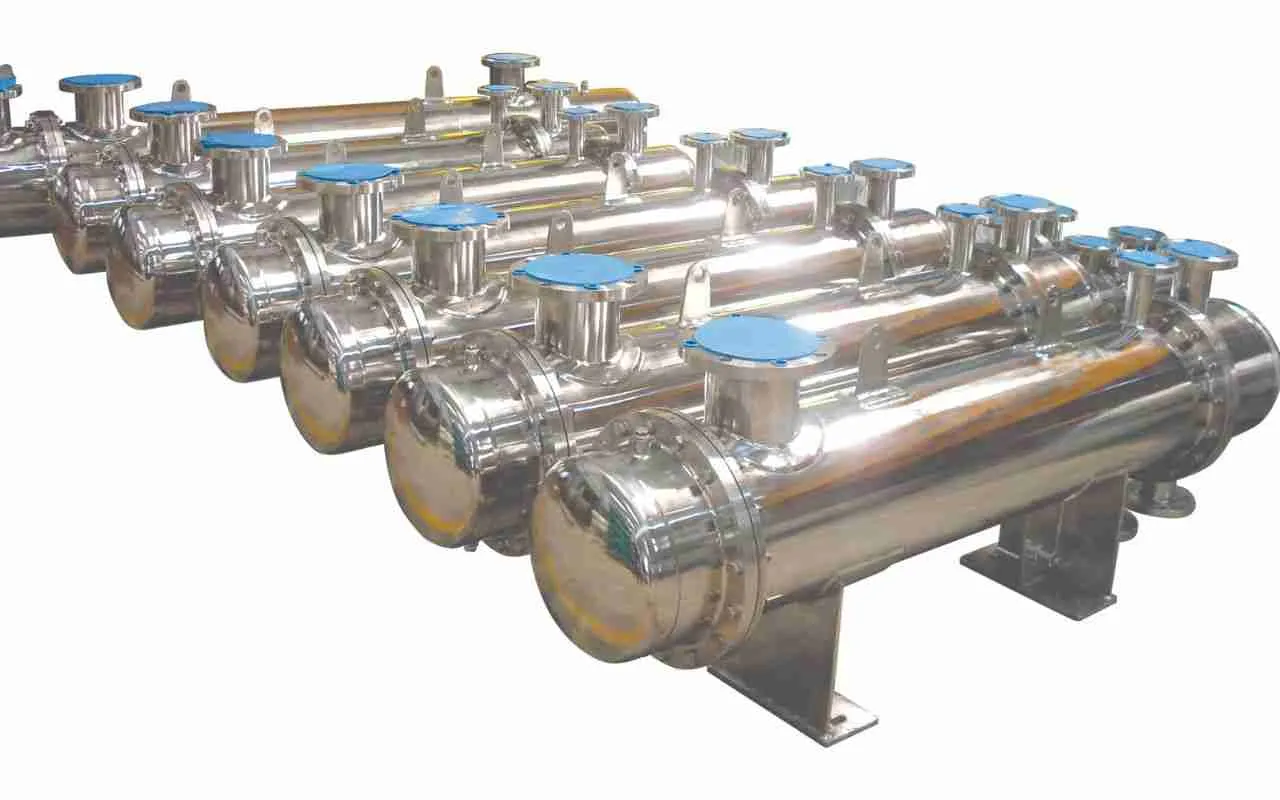

- Preheaters

- Pasteurisers

- Blanching & Pasteurisation of Fruits and vegetable particulates (fruit dices, slices, leafy vegetables, etc.)

- Aseptic Steriliser

- Aseptic filler

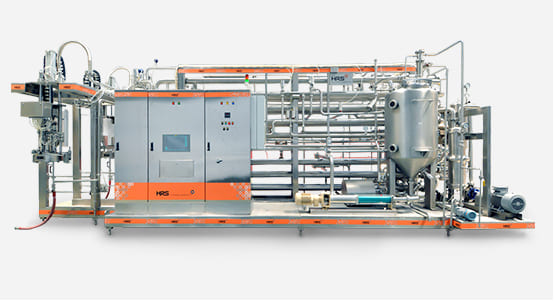

- HRS Monobloc Steriliser cum Filler

- Evaporation Systems for concentration of purees & pulps

- Turnkey Solutions for Pulp Processing

Aseptic Fillers

HRS Monobloc* Steriliser

Evaporation System for Fruits/Vegetables