Effective CIP procedures eliminate microbial contamination of the foods being processed to ensure safe food fit for consumption. CIP is a method of cleaning the interior surfaces of pipes, vessels, process equipment and other associated fittings, without disassembly. Single to multiple circuits integrated CIP systems from HRS are advantageous in reducing the consumption of water, chemicals, steam and power; eventually reducing the effluent discharge.

This approach is an advancement to local CIP setup, where each machine has an independent CIP module; thus ensuring the desired cleaning, and control of whole plant from one location.

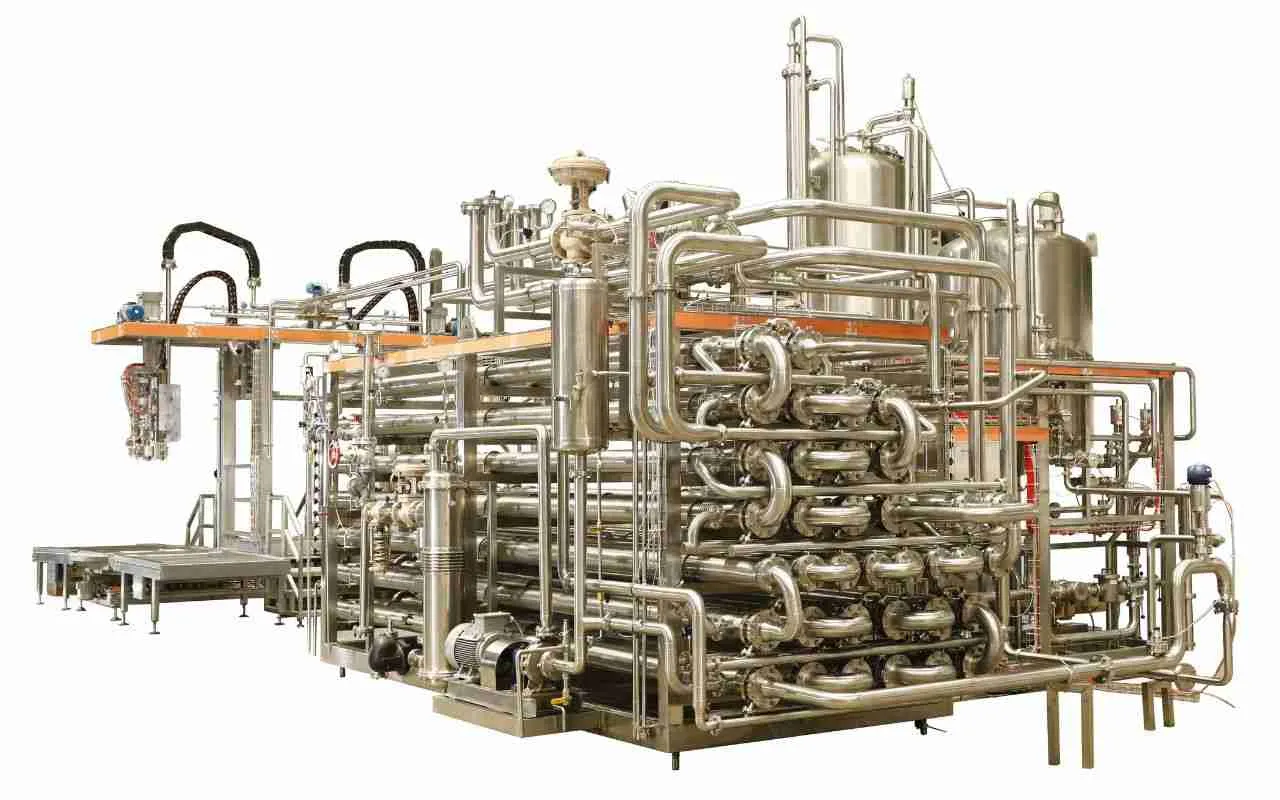

Triple Circuit CIP System

Triple Circuit CIP System